The installation of a few, full-scale biosolids thermal dryer system

Serves the growing population of the City of Murfreesboro and Rutherford County

Located just south of Nashville, Rutherford County is one of the fastest growing counties in Middle Tennessee. To support the constantly increasing population it serves, the Murfreesboro Water Resources Department (MWRD) continues to find new ways to improve its methods of water treatment and distribution. For over 50 years SSR has been a trusted advisor to MWRD in designing creative and advanced improvements and renovations at its facilities.

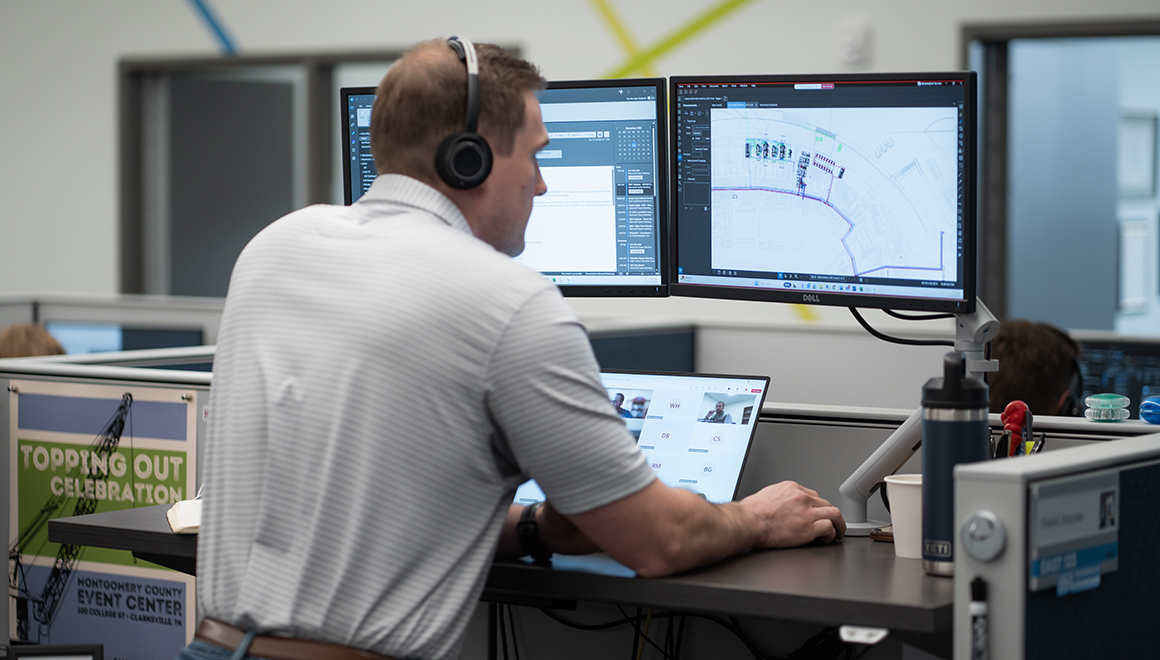

This partnership was instrumental in the installation of a new, full-scale biosolids thermal dryer system at the Murfreesboro Water Resource Recovery Facility. We recommended that the City initiate a small-scale or pilot project to verify drying performance objective could be met. In the procurement phase prior to the project launch, we protected the City of Murfreesboro by including language in the Request for Proposal solicitation that held the manufacturer liable in the event the dryer equipment failed to successfully perform. The document included specific performance criteria for the equipment to meet.

This criterion turned out to be crucial, as the equipment selected for the job ultimately could not achieve the specific performance metrics. During the small-scale project, we were on site for a number of weeks to collect samples, compile operations and test data, and observe the dryer performance. This data and documentation was later used to protect the interest of Murfreesboro. We reassessed project objectives because of the small-scale test. The City eventually provided SSR with a new project basis, which was to repurpose the existing truck bay of the biosolids dewatering building to house the new full-scale dryer installation. We contacted and evaluated multiple dryer manufacturers and selected the one that was able to install equipment in the truck to meet long-term biosolids drying requirements.

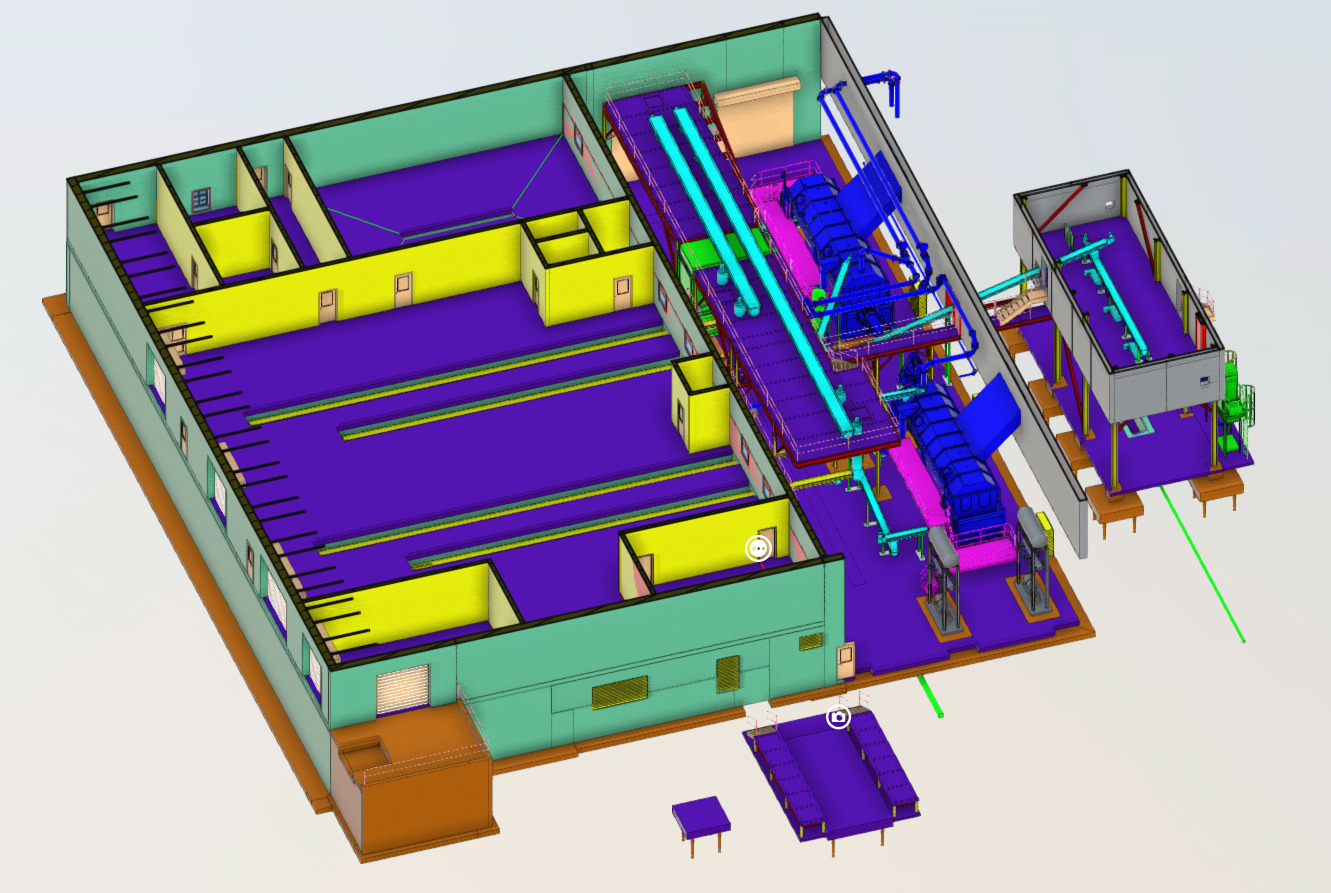

Our team then provided engineering design services to install a Komline-Sanderson paddle dryer system in the existing Biosolids Processing Building. Once complete, the full-scale biosolids thermal drying system will include wet cake and dried product conveyance equipment, a thermal fluid boiler system, modifications to the existing sludge cake conveyors, a truck loadout facility, loadout conveyor equipment, modifications to the existing sludge holding facilities, and all ancillary equipment and appurtenances for complete and operable systems. A standby generator will provide emergency electrical feed to the facility. The layout of the truck loadout facility has the capability to accommodate a future dried product storage silo and dried product conveyance.

The specifications of the Komline-Sanderson paddle dryer permitted the City to install dryers within the existing Biosolids Building truck bay, thus repurposing the space and saving the construction cost of a new dryer building. The dryers will permit MWRD to dry biosolids under average and peak conditions throughout the 2040 planning period.

Our support helps the City of Murfreesboro meet its goals for the benefit of the community. Estimated to be completed by 2027, the new dryer facility will produce Class A biosolids, creating a pathogen-free product to be used freely in agricultural lands, contributing to soil health and crop nutrition. In addition, drying biosolids will reduce truck traffic on City streets by 1,200 trucks per year. Such improvements enable MWRD to continue to support the community in new and sustainable ways.