Granular Activated Carbon – Past and Future Uses for Water Treatment

When is it ok to sacrifice our health for the sake of convenience? This has been a burning question for consumers and regulators as they work to implement a plan to reduce the hormone disrupting and cancer causing PFAS (Per- and Polyfluoroalkyl Substances) – also known as forever chemicals – polluting many of our source waters. While PFAS may not ring many household bells; these substances have been providing us many conveniences since the early 1960’s when companies like 3M and DuPont rolled out these man-made chemicals that would coat everyday items like frying pans and rain jackets. The many conveniences these chemicals provided resulted in widespread use. However, the heavy usage of these chemicals and their difficulty to be removed from the environment, have resulted in traces of these harmful chemicals being discoverable in the bloodstream of 99% of American bodies.

One of the most common and successful means to remove the PFAS chemicals is the use of Granular Activated Carbon (GAC). The success has been accredited to the adsorptive properties found in the carbon and its natural physical properties. Activated carbon is highly porous which makes it great for adsorption as the porosity allows compounds to pass through the annular spaces in the media. In fact, one gram of activated carbon is so porous that is has a surface area more than 32,000 SF. For comparison sake, a football field has a surface area of 57,600 SF meaning one gram of granular activated carbon has the same surface area as half of a football field! As water flows through carbon, the carbon also exerts an attractive force on contaminants found in the water, causing contaminants like PFAS to become trapped in the vast open space, removing it from the water. Because PFAS are designed to resist oxidation, physical separation processes like GAC is one of the best available technologies for the reduction of these types of harmful compounds.

Although the popularity of GAC has increased recently due to its high performance in the removal of PFAS and other emerging contaminants, the technology has been used in water treatment for many decades. GAC has been a proven source for removing other contaminants besides PFAS – most notably taste and odor issues – as well as organics. Over the past 13 years, SSR has been involved in the implementation of GAC for water treatment in numerous unique projects including retrofits, expansions, and green field water treatment plants across Tennessee including in Murfreesboro, Franklin, and Clarksville. Each installation has proven to provide our clients with reliable solutions that provide their customers with safe and excellent water quality.

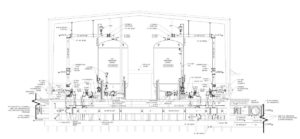

GAC gravity contactors.

In 2004, SSR provided the Murfreesboro Water Resources Department (MWRD) with design services for an upgrade at the existing Stones River Water Treatment Plant. The project included the addition of lime softening basins, membrane filtration, and the use of GAC. The membrane filtration would replace the existing mixed media filters as the primary means to remove pathogenic bacteria and other particulates from the softened water after the upgrade of the treatment plant. However, microfiltration membranes are not effective at removing dissolved contaminants, disinfection byproduct precursors or taste and odor causing compounds from treated drinking water. In order to remove these compounds, the existing filter beds were renovated with GAC in the plant expansion. The design was unique in that the piping modifications allowed MWRD to operate the GAC before or after the membranes. To date, MWRD has found optimum treatment with the GAC following the membrane filtration, so they’ve yet to use the versatility of the flow altering feature. The hydraulic profile also worked out so that secondary pumping would not be needed regardless of which flow pattern was used as the membrane feed pumps would be able to serve as the primary drivers to push water through both the membranes and GAC.

In 2012, SSR began the design of the City of Franklin’s upgrade to their existing Water Treatment Plant and in 2017 their membrane filtration and GAC adsorption plant came online. As part of the project, SSR designed four GAC pressure vessels downstream of the membranes and an Ultraviolet Advanced Oxidation Process (UV-AOP). The primary function of the pressurized GAC contactors in this application was to remove the hydrogen peroxide residual leaving the UV-AOP process. The mechanism of removal is through conversion of peroxide to oxygen gas within the carbon media. Additionally, the carbon contactors provide a secondary benefit of reducing remaining organics, taste and odor compounds, disinfection byproducts, and emerging contaminants. Like the traditional sand filters that were retrofitted for the MWRD project, flow enters at the top of the pressure vessels, passes down through the media, and exits at the bottom of the tank. Backwashing the carbon media is achieved by reversing the flow, and bringing clean, potable water into the bottom of the unit, and drawing it off the top of the unit. To allow for additional treatment and operator flexibility, the system was designed to include interconnecting valves and piping to allow the GAC operation in series or parallel. This arrangement also allows operators the ability to place one vessel offline for backwash operations or carbon regeneration/replacement without requiring the entire unit process to be removed from service. The pressurized GAC vessels also allow the membrane feed pumps to push flow through the activated carbon and into the finished water clearwells without breaking pressure, thus eliminating the need for a secondary pumping system.

Pressurized carbon contactors.

One of the many benefits of the addition of GAC contactors is its superior performance compared to powdered activated carbon (PAC). GAC is much more effective at taste and odor removal compared to PAC, and GAC maximizes adsorption capacity of the carbon, allowing it to treat for a wider range of contaminants. GAC requires less handling, storage space and equipment compared to PAC. With the addition of GAC at the Franklin Water Treatment Plant, the use of PAC at the facility was discontinued.

The most recent GAC application that SSR has been involved with began in 2018, when SSR began the design of the North Clarksville Water Treatment Plant (NCWTP), the first greenfield water treatment plant for Clarksville Gas & Waters (CGW) in 70 years. Wanting to duplicate the existing plant as much as possible for ease of operations and maintenance of the two facilities, the new plant would incorporate the same technologies as the existing plant including coagulation, flocculation, sedimentation, and membrane filtration. One notable difference between the two plants would be the inclusion of pressurized GAC contactors downstream of the membranes, like what was installed at the Franklin Plant.

Although the design of the NCWTP treatment process was nearly identical to the existing plant, the source water between the two plants was slightly different. While the existing plant is located upstream of the downtown area, the new plant intake would be located downstream of the confluence of another river and several combined sewer overflows from the City of Clarksville. Sampling was provided during the preliminary design of the plant and confirmed no substantial differences in the waters however the grab samples could only account for certain times and flows and thus provided some limited results. The installation of GAC would provide additional treatment if variations in source waters are experienced that may result in operational changes between the two plants. During the preliminary sampling, no evidence of PFAS or other emerging contaminates were discovered, however regulation of PFAS in drinking water supplies appears to be imminent and other emerging organic chemical regulations are likely not far behind. In case PFAS or other emerging contaminants appear in the source water, the GAC contactors at the NCWTP will be ready to remove them.

The GAC pressure contactors at NCWTP will also provide additional Total Organic Carbon (TOC) and geosmin/MIB (2-methylisoberneol) removal. A bypass around the GAC units was also provided to provide operational flexibility and extend the life of the carbon by placing the units offline during the winter months when colder water temperatures decrease the geosmin/MIB levels.

Granular Activated Carbon treatment has been around since the 1940’s and its effectiveness for treatment of organics, taste and odor, and emerging contaminants has proven its use will not be disappearing anytime soon. Even with the likely increased usage of the carbon, it’s availability shouldn’t falter as the use of GAC is an environmentally conscious treatment option. Carbon used in water treatment processes can be reused following reactivation through thermal oxidation, a process which burns off any impurities and allows the carbon to be used multiple times for the same application. The reactivation process is also more cost effective than mining for virgin carbon, providing additional benefits to the users. With its proven treatment track record and sustainable availability, granular activated carbon has proven it will continue to be a solution to many of our drinking water problems both today and in the future.